We are aware of our environmental impact and we continuously work to reduce the environmental footprint from our operations. Furthermore, Rain Carbon is focused on developing more environmentally friendly products to ensure our customers have the raw materials they need to attain their sustainability goals.

Rain Carbon is committed to responsible value creation. Resource efficiency and carbon productivity represent the foundation of our business model.

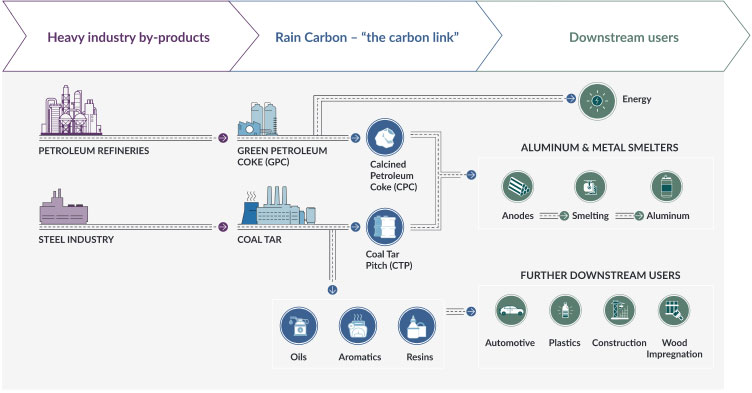

Rain Carbon's business model is driven by resource -efficiency, as it is based on the conversion (upcycling) of by-products from the oil and steel industries into value-added raw materials essential for other industries. Rather than relying on virgin raw materials, we transform by-products of multiple industries into more useful and value-added products while also preventing them from being disposed of as waste or burned as a low-grade, high-carbon fuel source. The minimization of waste quantities is an important guiding principle for us.

This approach makes Rain Carbon the critical carbon link between heavy industry and downstream users.

Our Contribution to a Decarbonized Economy

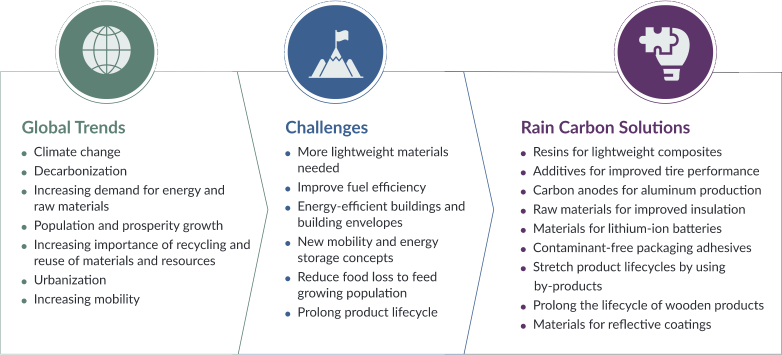

In response to concerns about climate change, companies are aggressively working to decrease carbon emissions. Energy efficiency and the reduction of CO2 emissions are key elements in Rain Carbon's drive to support a decarbonized future.

At our calcination sites the high-temperature flue gas generated during the calcining process provides significant opportunity for energy conservation and recycling. Rain Carbon has made major investments in waste-heat recovery systems at our U.S. calcination facilities in Lake Charles, Chalmette and Norco and in Vizag, India.

Energy management, energy efficiency and energy savings are topics of great importance when it comes to sustainability.

Process Innovations and Initiatives Improving Air Quality

Tackling local air quality is important to Rain Carbon, and it has become increasingly important to communities, governments and other stakeholders. We have implemented different measures to reduce the potential impact of our activities on the air quality for our communities.

Rain Carbon minimizes SO2 emissions at selected calcination facilities by utilizing state-of-the-art SO2 flue-gas desulfurization (FGD) systems (Lake Charles, Chalmette, Norco, Vizag).

In 2010, we initiated the leak-detection-and-repair project to reduce benzene emissions at our distillation facility in Zelzate, Belgium.

While Rain Carbon’s production processes have a small footprint for NOx emissions, opportunities to reduce them further have been identified and initiatives to do so are underway.

Rain Carbon produces essential materials that are building blocks for addressing global challenges, and our carbon-based products are critical to many industries around the world. Anode materials for the production of aluminum, raw materials for lithium-ion batteries, concrete additives for high-performance buildings, and additives to protect bridges and marine structures are only a few examples. Our products also make possible a wide range of items we use every day such as paints, packaging and tires.

The combination of production and energy generation is beneficial as the energy/steam is used by our plants, other companies and the local grid. This reduces the need to burn additional fossil fuels to generate the same amount of energy, which offsets the accompanying CO2 emissions.

The combination of production and energy generation is beneficial as the energy/steam is used by our plants, other companies and the local grid. This reduces the need to burn additional fossil fuels to generate the same amount of energy, which offsets the accompanying CO2 emissions.