Circularity and Responsible Production

The chemical industry has increasingly integrated products into its portfolio with reduced environmental footprints, as part of efforts to promote circular economies and value chains.

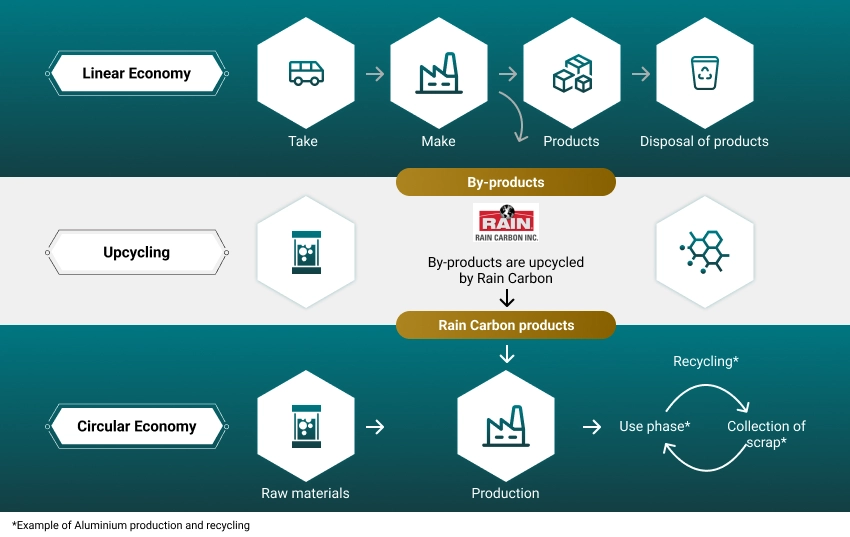

At Rain Carbon, we prolong the lifetime of carbon-containing materials from the linear economy, through the upcycling of by-products from the steel and petrochemical industries that would otherwise be combusted for energy or disposed of in landfills. We convert those raw materials into value-added products that enable higher circularity levels in downstream applications, like aluminum production or steel scrap recycling.

Our products also improve sustainability in their end-use applications, such as:

- Maximizing the efficiency of lithium-ion batteries for e-mobility in terms of number of charging cycles

- Enabling tires to reduce their rolling resistance

- Extending the life of critical infrastructure through long-lasting coatings

In the future, we see opportunities to expand our upcycling activities by broadening our raw material base and supporting customers with their circularity ambitions.

By offering more environmentally friendly products, we can make a positive contribution toward the global challenges of climate change, declining biodiversity, environmental pollution and resource waste, while reducing the environmental footprint of our company and products. One example is the ISCC PLUS-compliant Rain Carbon product line (based on mass allocation) from our advanced materials business.

Advanced Materials ISCC PLUS Initiative

In our advanced materials business, we have developed additional indicators to monitor the number of products made from sustainable feedstocks from 2022 onward. Sustainable feedstocks refer to all types of sustainable carbon, such as bio-based streams and those derived from recycling.

This initiative includes certification under the International Sustainability & Carbon Certification (ISCC) PLUS scheme. ISCC is a globally recognized organization that certifies bio-based and recycled feedstocks across the entire value chain, from source to end-product. Using the concept of mass balancing, amounts of sustainable raw materials are added at the beginning of the value chain and mathematically allocated to the respective amounts of products. Mass balancing and allocation ensure that an equivalent amount of sustainable raw materials is present in the value chain. Overall, the chemical industry is becoming more sustainable, with increasing proportions of ISCC PLUS-compliant material.

With the ISCC PLUS certification for our sites in Germany, we will be able to offer certain 100% ISCC PLUS-compliant Rain Carbon products based on mass allocation. We believe this initiative is an important next step in transparently increasing the sustainability and circularity levels of Rain Carbon’s value chains.

NOVARES® resins decrease a car’s energy consumption

Research and development in the auto¬motive-tire industry has shown that certain additives in tire compositions can reduce the energy consumption of cars. Our internal analysis has shown that the addition of selected NOVARES® resins in tire compounds results in a 16% better rolling resistance than the standard rubber mixture. Based on internal estimates, this improved rolling resistance has the potential to save 0.82 tons of CO2 emissions over the lifetime of an average family car (mileage of 200,000 km).