Product Carbon Footprint

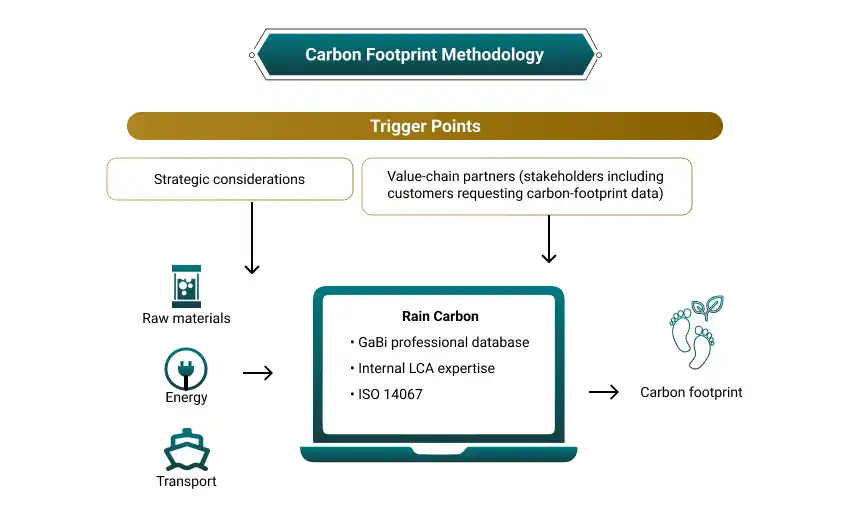

Product carbon footprint studies are a tool to assess the sustainability of our overall product portfolio, particularly for climate change. The assessments are globally standardized and have become an important point of reference for industries and global value chains.

With the aim to be transparent in our environmental impact throughout the value chain, we have established infrastructure to model carbon footprints for our products according to ISO 14067.

In recent years, we have conducted the following assessments:

2020

2021

- Benzene-production facility in Zelzate, Belgium

- CARBORES® products at Castrop-Rauxel, Germany

2022

- Aluminium value chain study

- NOVARES® resins, pitch, naphthalene, creosote oil and carbon black oil

2023

- Phthalic anhydride production facility in Zelzate, Belgium

- Calcined petroleum coke at US calciners, USA

2024

- NOVARES® Resins in Duisburg, Germany

- NOVARES PURE® resins in Castrop-Rauxel, Germany

Aluminum value chain

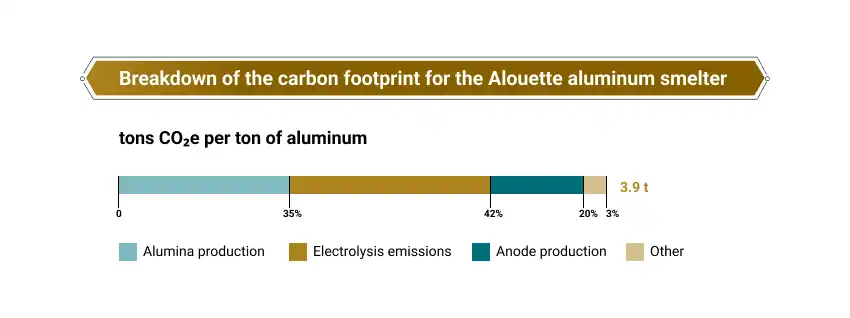

The results of our aluminum value chain study were published in a peer-reviewed technical paper in the Journal of Metals in September 2022. The study shows that the Aluminerie Alouette smelter in Canda produces among the lowest carbon primary aluminum in the world, with total Scope 1, 2 and 3 emissions of only 3,914 kg CO2e/ton of aluminum. Some hydroelectric-powered smelters achieve the <4 tons CO2e/ton of aluminum target needed to qualify their product as low-carbon aluminum by including only Scope 1 and 2 emissions. For Alouette to achieve <4 tons with all cradle-to-gate emissions included is a significant achievement. It means their carbon footprint is approximately 75% lower than the average global aluminum smelter and approximately 25% lower than the average Canadian hydroelectric-powered smelter.

According to this scientific assessment the CPC from the Company’s Lake Charles site has a CO2 footprint that is 16% lower than CPC provided from a calciner without waste heat recovery and power generation. The total anode production supply chain including green petroleum coke, coal tar, CPC and coal tar pitch (CTP) production contributes 20% to the overall carbon footprint of the Alouette smelter.